Inconel Metal spin forming

Metal spinning is used to form a wide variety of high-performance, axially symmetric parts. This metalworking process is compatible with both traditional and exotic metals – such as Inconel.

Inconel is very suitable for use in extreme environments, high temperature and high pressure environments

While metal spinning Inconel can be challenging, skilled operators will nonetheless be able to produce high-quality, high-strength Inconel parts.

In the realm of metalworking, precision and innovation stand as pillars of progress. Spin forming is a superior industrial solution for versatility and efficiency in metal forming. Dive into the intricacies of Altron’s Inconel metal spin forming, a groundbreaking advancement.

What is Inconel Materials?

Inconel is a nickel alloy containing varying amounts of nickel, chromium and iron, with nickel accounting for the largest percentage.

It is a family of austenitic nickel-chromium-based high-temperature alloys known for their excellent resistance to high temperatures, corrosion and oxidation. Inconel alloys are primarily used in aerospace, gas turbine engines and marine environments, where they exhibit exceptional strength and stability.

The exact quantities of the metals comprising Inconel will ultimately impact its properties and performance. Inconel comes in a variety of unique forms. Alloys of Inconel include:

Inconel 600

Inconel 600 is a nickel–chromium alloy with good resistance to oxidation at high temperatures.

High nickel content, it can resist chloride ion stress corrosion cracking,

It is often used in chemical and food processing, furnace manufacturing, process equipment, etc.

Inconel 617

Inconel 617 is a high-temperature nickel–chromium–cobalt–molybdenum alloy that resists corrosion and oxidation very well. Its many applications include gas turbine engine ducting and combustion liners.

It is a common material in chemical processing due to its resistance to a wide range of aqueous corrosive media.

Inconel 625

Like Inconel 600, Inconel 625 is a nickel-based alloy with great corrosion and oxidation resistance. It maintains outstanding strength and durability within temperatures ranging from cryogenic to those in excess of 2,000° F. Inconel 625 owes its strength to its composition of columbium and molybdenum, which make it suitable for applications such as:

- Heat shields

- Furnace hardware

- Gas turbine engine ducting

- Combustion lines/spray bars

- Chemical plant hardware

- Special seawater applications

The selection of the most appropriate Inconel alloy depends on the conditions in which it will be deployed. At Helander, we work closely with our clients to determine the most optimal type of Inconel for their needs.

Inconel 718

All Inconel alloys have high strength and elasticity.

But Inconel 718 is known for its tensile strength, impact strength, and high temperature resistance up to 1850-2000° F.

These properties make Inconel 718 particularly suitable for aircraft engines and other aerospace components.

More broadly, Inconel 718 is an excellent choice when environmental conditions may compromise other high-performance m etals. Many oil and gas components are manufactured from Inconel 718.

Inconel can be forged into a variety of components for harsh applications, including valves, wheels, fasteners, spacers, and much more.

Inconel is challenging to work with and requires special expertise and tooling.

The alloy can be machined after annealing or age hardening; age hardening produces a smooth surface finish, while annealing increases durability, depending on the properties required.

Altron’s team has extensive experience in manufacturing metal spun parts using Inconel.

What is Inconel Used For?

Although the types and compositions of Inconel may vary, all Inconel alloys are marked by their high strength, superior corrosion and oxidation resistance, and durability in the face of high heat and pressure – they function very well even in harsh environments.

Inconel retains enough tensile strength at high temperatures to hold moderate loads under extreme stress. For example, Inconel 625 retains weights of up to 13.3 ksi at 2,000°F. Inconel also works well in manufacturing processes that cycle workpieces through low- and high-temperature environments in rapid succession.

Most Inconel alloys retain excellent oxidation resistance at high and low temperatures, which make them a great fit for processes where temperatures tend to fluctuate from cryogenic lows to heat-treatment highs within short periods of time. Inconel also performs well in any environment that subjects materials to caustic corrosion, stress corrosion, or aqueous corrosion.

Applications Across Metal Spinning Industries

The versatility and performance of Inconel metal spin forming make it the material of choice for the aerospace industry, where reliability, durability and performance are non-negotiable. Let us explore some notable applications:

- Aerospace and Defense: In the aerospace and defense sectors, where safety and reliability are paramount, Inconel metal spin-formed components find widespread use in critical systems such as jet engines, rocket propulsion systems, and structural components of aircraft and spacecraft. The ability to withstand high temperatures, mechanical stress, and corrosive environments makes Inconel an ideal choice for such demanding applications, ensuring the integrity and functionality of vital systems.

- Oil and Gas: In the oil and gas industry, where operations often take place in harsh and corrosive environments, the reliability of equipment and components is crucial for maintaining operational efficiency and safety. Inconel metal spin-formed parts, with their exceptional resistance to corrosion, erosion, and high-pressure conditions, find application in various critical components, including valves, fittings, and piping systems, ensuring long-term performance and durability in demanding oilfield operations.

- Power Generation:In the realm of power generation, where efficiency and reliability are paramount, Inconel metal spin forming plays a pivotal role in the production of turbine components, heat exchangers, and exhaust systems for gas turbines and nuclear reactors. The ability of Inconel alloys to withstand high temperatures and corrosive environments ensures the longevity and performance of critical components, contributing to the uninterrupted operation of power plants and utilities.

- Medical Devices: In the medical industry, where precision, biocompatibility, and sterilizability are essential requirements, Inconel metal spin forming finds application in the manufacturing of implantable medical devices, surgical instruments, and diagnostic equipment. The superior mechanical properties and corrosion resistance of Inconel alloys make them well-suited for such applications, ensuring the safety and efficacy of medical devices in demanding healthcare environments.

Introduction to Inconel

Among the myriad materials utilized in spin forming, Inconel holds a distinct position. Developed by the International Nickel Company (INCO) in the 1940s, Inconel is a family of superalloys renowned for their exceptional resistance to high temperatures, corrosion, and mechanical stress.

Composed primarily of nickel, chromium, and iron, with additions of other elements such as molybdenum and niobium, Inconel alloys exhibit superior mechanical properties under extreme conditions, making them ideal for demanding applications.

Inconel metal spin forming Case

Understanding Metal Spinning Forming

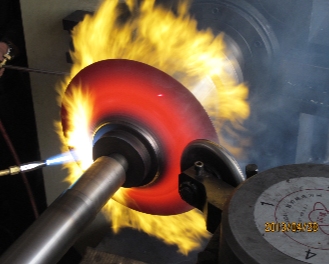

At its core, spin forming is a metalworking process that involves the rotation of a metal disc or tube at high speeds while applying pressure, thus shaping it into the desired form.

This method allows for the creation of complex geometries with remarkable accuracy and repeatability. The process finds application across diverse industries, including aerospace, automotive, and electronics, owing to its ability to produce lightweight yet durable components.

Advantages of Inconel Metal Spinning

The marriage of spin forming with Inconel alloys offers a plethora of advantages that are unrivaled by conventional manufacturing methods. Let us explore some of the key benefits:

Superior Strength and Durability

Inconel alloys are known for their outstanding mechanical properties, including high tensile strength and fatigue resistance.

These properties are further enhanced by harnessing the power of spin forming, resulting in components with unrivaled strength and durability, which are critical for applications under extreme operating conditions.

Enhanced Corrosion Resistance

One of the hallmark traits of Inconel alloys is their outstanding resistance to corrosion, particularly in harsh environments characterized by high temperatures, oxidation, and chemical exposure.

Through precise control afforded by spin forming, manufacturers can create intricate geometries with smooth, uniform surfaces, minimizing the risk of corrosion and prolonging the lifespan of components.

Complex Geometries with Precision

The versatility of spin forming allows for the creation of complex geometries with remarkable precision and consistency.

Whether it be intricate contours, seamless transitions, or tight tolerances, Altron’s expertise in Inconel metal spin forming empowers designers and engineers to push the boundaries of innovation, realizing designs that were once deemed unattainable.

Cost-Efficiency and Time Savings

In addition to its technical prowess, Inconel metal spin forming offers tangible benefits in terms of cost-efficiency and time savings.

The streamlined nature of the process, coupled with the ability to produce near-net shapes with minimal material wastage, translates into reduced production lead times and lower overall manufacturing costs, making it an economically viable solution for both small-scale prototypes and large-scale production runs.

Inconel Metal spinning Conclusion: Future of Manufacturing

In conclusion, Altron’s Inconel metal spin forming represents a paradigm shift in the realm of advanced manufacturing technologies. The unique properties of Inconel alloys combine precision and versatility in spin forming to create high-performance components with unmatched strength.durability, and reliability.

As industries continue to evolve and demand higher and higher standards of performance and efficiency,the combination of Inconel alloy and spin forming technology plays a key role in driving progress in various fields.