CNC Metal Spinning VS Deep Drawing

Deep drawing and CNC metal spinning in the manufacturing process of metal forming are the main methods of sheet metal forming! CNC Metal Spinning VS Deep Drawing Each has its own advantages!

Choose the process according to the actual needs of the manufacturer; deep drawing has high initial development costs and high production efficiency! CNC metal spinning has low development costs, high convenience, and is suitable for small and medium batch production!

Principles of Metal Spinning and Deep Drawing

Deep Drawing

The cooperation of the male and female dies controls the flow and plastic deformation of the metal sheet, and multiple stretching or single forming is performed. During the deep drawing process, the metal material undergoes plastic deformation. When the proportion and amplitude of deep drawing are large, annealing must be performed to improve the material properties.

CNC Metal Spinning

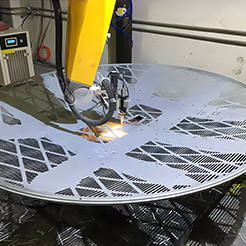

The tail of the metal spinning machine provides hydraulic clamping force, driving the metal sheet and the main shaft to rotate. The CNC program controls the forming path of the spinning roller, and performs multiple rolling from point to line and then to surface. It can complete complex actions such as turning, beading, flanging, cutting, etc.

Comparison of advantages of metal spinning & deep drawing

| List | Deep Drawing | CNC Metal Spinning |

| Accuracy | Limited by the mold! There is a small error in mass production. | The precision is controlled by CNC machine tools and systems and can be flexibly adjusted! |

| Mold cost | The cost is high! Making concave and convex molds | Usually only a core mold is needed, or moldless; low manufacturing cost! |

| Production Efficiency | The forming efficiency of simple shapes is high; for complex shapes or larger size workpieces, multiple stretching efficiency is reduced! | It can be used for sample testing and batch continuous production, and is suitable for forming workpieces with large diameters or complex contours and multiple processes! |

| Metal utilization | The thinning rate is about 10%, and the proportion of edge pressing materials is high! The utilization rate is average. | The material thinning rate is relatively high, about 30-50%; no edge pressing is required, and the material utilization rate is high! |

| Application | Simple cylindrical products, few processes, and high production requirements. | It is widely used to produce workpieces with complex processes and contours. |

Video of Deep Drawing and CNC Metal Spinning

Industrial fan parts metal forming case:

The impeller shrouds of industrial fans are made into deep drawing dies after the shapes are determined in large quantities, which has higher production efficiency! CNC metal spinning is used for preliminary sample testing! It is easier to modify and adjust the contour and size.

CNC spinning is used for small batch production, which saves the cost of developing molds, shortens the time cycle, and adjusts the size and contour data more flexibly!

More Metal Forming Samples

If your company is looking for a metal forming supplier, please contact Altron. I will provide you with a variety of metal forming manufacturing process options! Product parts that meet different shapes, materials, and application fields!

Engineer Joby is online 24 hours a day to solve your metal forming problems!

ALTRON‘s Metal Spinnning Froming Services:

WhatsApp: +86 156 2739 7226

E-mail: info@auto-altron.com

Hot Metal Spinning Process

Centrifugal fan impeller internal welding robot

Lampshade metal polishing process

Metal spinning products 3D laser cutting