Altron’s Metal Spinning OEM Service For Stainless Steel

Metal Spinning OEM Service

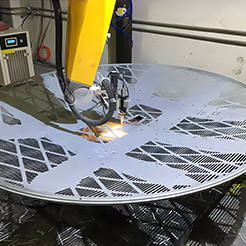

CNC metal spinning Services at Altron Stainless Steel. The company’s OEM (Original Equipment Manufacturer) services cater to diverse industries, ensuring high precision and durability in every product. Metal spinning, also known as spin forming or spinning, involves rotating a metal disc or tube at high speeds and shaping it over a preformed mold. This method is crucial for producing symmetric, cylindrical, or conical parts with seamless finishes.

Altron’s CNC metal spinning service is versatile and can handle various sizes and thicknesses of stainless steel. By leveraging advanced CNC (Computer Numerical Control) machines and experienced technicians, Altron ensures each product meets stringent industry standards. Their capabilities extend from small-scale prototypes to large production runs, providing customers with flexibility and efficiency.

Communication of Technical Requirements for Metal Spinning Products

Clear and precise communication of technical requirements is essential in metal spinning. Altron emphasizes a thorough understanding of client specifications to deliver optimal results. Clients must provide detailed drawings, specifications, and material requirements. This information forms the basis of the production process, ensuring that the final product meets the desired specifications.

Altron employs a collaborative approach, engaging with clients during the initial design phase to address potential challenges and optimize the manufacturing process. This proactive communication helps in identifying the most suitable materials, techniques, and tolerances required for each project. Facilitating an open online Google meeting.

Introduction to Metal Forming Processing Capabilities

Altron’s metal forming capabilities extend beyond metal spinning. The company offers a comprehensive suite of metal forming services, including deep drawing, stamping, and hydroforming. These processes enable the creation of complex shapes and structures, enhancing the versatility and application of metal components.

Deep drawing involves pulling a metal sheet into a die to form a hollow shape, which is ideal for producing deep, cylindrical parts. Stamping, on the other hand, uses a press to cut or shape metal into desired forms. Hydroforming utilizes high-pressure hydraulic fluid to shape ductile metals into lightweight, structurally strong components. Choosing different processes has different advantages.

Altron’s expertise in these processes allows them to offer integrated solutions, combining multiple forming techniques to achieve the best results. This integration ensures that the final products exhibit superior strength, precision, and aesthetic quality.

Metal Forming OEM Processing Process

The CNC metal spinning process at Altron follows a structured and meticulous approach. The process begins with a detailed review of the client’s requirements and specifications. This initial phase includes feasibility studies, material selection, and design optimization to ensure the project is viable and cost-effective.

For metal spinning, this involves mounting the metal blank onto a lathe and spinning it at high speeds . The CNC program controls the metal spinning process. this process, continuous monitoring and adjustments ensure precision and consistency.

Post-production steps include trimming, polishing, and heat treatment to enhance the properties and appearance of the final product. Altron’s quality control team conducts rigorous inspections at each stage to ensure compliance with industry standards and client specifications. This systematic approach guarantees high-quality metal components that meet or exceed expectations.

Metal Spinning Sample Delivery and Establishment of Technical Files

Before full-scale production, Altron provides sample deliveries to clients for approval. These samples allow clients to verify the design, fit, and functionality of the components.

The sample delivery phase is crucial for identifying any necessary modifications and ensuring the final product meets all requirements.

Upon approval of the samples, Altron establishes comprehensive technical files for each project. These files include detailed documentation of the production process, material specifications, quality control measures, and any modifications made during the sample phase.

Maintaining accurate technical files ensures traceability and consistency in future production runs, facilitating seamless repeat orders and long-term partnerships with clients.

Core Factors of Stainless Steel CNC Metal Spinning

Several core factors influence the success of stainless steel metal spinning at Altron. Material selection, tooling, and process control are paramount.

Stainless steel has excellent corrosion resistance, strength and durability.

The key factor: High-quality mandrels, rollers, and other tools are essential for achieving precise shapes and smooth finishes. Altron invests in advanced CNC machinery and custom tooling solutions to meet diverse project needs.

CNC metal spinning process elements:

Program control speed

Pressure parameters

Temperature parameters

Adjust each parameter to control the data within the normal range to ensure production quality.

Altron’s expertise in process control enables them to produce complex shapes with tight tolerances and superior surface finishes.

Quality Inspection of Metal Spinning Products

Quality inspection is an integral part of the Altron metal spinning process, from raw material selection to final product delivery.

This comprehensive approach ensures that each component meets stringent quality standards and customer specifications.

Initial inspection focuses on verifying material properties and dimensions.

Production process: measuring the shape, thickness and surface finish of parts to ensure the stability of metal spinning mass production.

Product-specific accuracy requirements are checked using measurement tools: laser scanners and coordinate measuring machines.

Final inspection: Product spot checks for dimensional accuracy, surface integrity.

Altron is certified to industry quality standards, including ISO 9001. This certification underscores their commitment to continuous improvement and excellence in metal spinning services.

Conclusion

Altron’s CNC metal spinning services for stainless steel exemplify precision, quality, and versatility.

By leveraging advanced technology, skilled technicians, and a comprehensive understanding of client requirements, Altron delivers superior metal components for various applications.

Their commitment to quality, innovation, and customer satisfaction makes them a leader in the metal forming industry.

Through meticulous process control, rigorous quality inspections, and proactive communication, Altron ensures that every project meets the highest standards of excellence.

ALTRON‘s Metal Spinnning Froming Services:

WhatsApp: +86 156 2739 7226

E-mail: info@auto-altron.com

Hot Metal Spinning Process

Centrifugal fan impeller internal welding robot

Lampshade metal polishing process

Metal spinning products 3D laser cutting