Altron’s CNC metal spinning process solution

In the realm of metalworking, precision and efficiency reign supreme. Altron, a pioneering force in the industry, has harnessed cutting-edge technology to perfect the art of CNC metal spinning. This blog delves into the intricacies of Altron’s CNC metal spinning process, exploring its various facets and applications.

Manual Metal Spinning: Honing Craftsmanship

Manual spinning, the cornerstone of metal shaping, epitomizes artisanal skill and precision. Craftsmen meticulously mold metal sheets by hand, leveraging years of experience and keen eye for detail. While time-consuming, manual spinning allows for unparalleled customization and finesse, making it indispensable for intricate designs and prototypes.

Automatic CNC Machine Spinning: Efficiency Redefined

In contrast to manual spinning, automatic machine spinning embodies efficiency and consistency. Altron’s state-of-the-art CNC machines automate the spinning process with unparalleled precision. Computer-guided algorithms meticulously control every movement, ensuring uniformity and repeatability across large production runs. This automated approach drastically reduces lead times and minimizes human error, making it ideal for mass production.

Performance of Different Metal Sheet Spinning Processes: A Comparative Analysis

When evaluating the performance of different metal sheet spinning processes, several factors come into play, including speed, accuracy, and versatility. Manual spinning, while offering unparalleled customization, is inherently slower and labor-intensive. Automatic machine spinning, on the other hand, excels in speed and consistency but may lack the nuanced touch of manual craftsmanship.

Application of Metal Spinning Technology: Versatility Unleashed

The applications of metal spinning technology span across diverse industries, from aerospace and automotive to lighting and architecture. Its ability to seamlessly shape various metals, including aluminum, stainless steel, and copper, makes it a versatile choice for manufacturing complex components and decorative elements. Whether crafting intricate aircraft components or elegant lampshades, metal spinning technology offers endless possibilities.

Selection of CNC Spinning Machines: Key Considerations

Choosing the right CNC spinning machine is paramount to achieving optimal results. Factors such as spindle power, maximum sheet thickness, and tooling options must be carefully considered to meet specific project requirements. Altron’s comprehensive range of CNC spinning machines caters to various needs, offering flexibility, precision, and scalability for diverse applications.

The Most Perfect CNC Spinning Process Solution

In an era dominated by technological advancements, concerns over AI traces in manufacturing processes have become increasingly prevalent. Altron addresses these concerns head-on by integrating cutting-edge AI algorithms into its CNC spinning process. By leveraging machine learning and advanced data analytics, Altron ensures complete traceability and accountability throughout the manufacturing lifecycle, providing customers with peace of mind and unparalleled quality assurance.

In conclusion CNC metal spinning process

Altron’s CNC metal spinning process represents the pinnacle of precision engineering and innovation. From manual craftsmanship to automated efficiency, Altron seamlessly blends tradition with technology to deliver superior results across a myriad of applications. With a steadfast commitment to quality and innovation, Altron continues to push the boundaries of what’s possible in the world of metalworking.

ALTRON‘s Metal Spinnning Froming Services:

WhatsApp: +86 156 2739 7226

E-mail: info@auto-altron.com

Altron's CNC metal spinning process solution

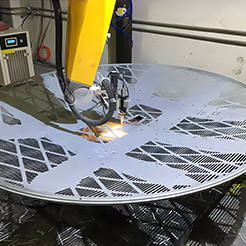

Hot Metal Spinning Process

Centrifugal fan impeller internal welding robot

Lampshade metal polishing process

Metal spinning products 3D laser cutting